Measuring technology for optical low-coherence interferometry (OLCI, HP OLCI)

These optical measuring devices were developed for contactless measurement of thicknesses and profiles. The measuring process uses the principles of optical coherence tomography (OCT), in which light with a low coherence length is used together with an interferometer to measure distances. The measured objects are scanned at several points. A moveable sensor head can scan the surface profile and/or thickness profile. The depth resolution is only limited by the coherence length of the light source. It is also dependent on the refraction index of the sample. The device acts as a server (can work on a stand-alone basis and has an integrated computer), which can be contacted using one or more software clients via a simple TCP/IP connection. This makes it possible to display the results simultaneously or analyze them at various points.

OLCI by OPTEG – the key points:

- Optical thickness and profile measuring device on up to 12 channels

- HP OLCI on up to 6 channels

- Material to be measured must be transparent for the wavelength used

- Parallel measurement of optical disc thickness

We can also develop custom OLCI systems for any kind of measuring setup, according to customer wishes. Depending on the needs and application, we can produce axis systems or devices for stationary measurement. We would also be happy to integrate the measuring device into a production process.

Light sources with varying wavelengths are used depending on the application.

OLCI stands apart compared to other procedures. Although very high precision and resolutions (Z resolutions in the range of 0.1 nm) are possible with white-light interferometry or confocal microscopy, these systems cannot “go in deep” and therefore cannot measure thicknesses or films. They also have problems with large aspect ratios (side ratio, width to height). A HP OLCI device developed by OPTEG is more precise than standard OCT processes.

Typical applications

Glass industry: optical glass (thickness, flat glass, glass in the automotive sector, glass cylinders, center thicknesses on lenses)

Opthalmic industry: contact lenses, IOLs, center thickness on spectacles lenses

Industry: surface coatings, films, barrier coatings, adhesives, packaging, paints, films, live determination of etching rates

Semiconductor industry: solar cells and wafer thickness measurement

Medical technology: tubes (wall thicknesses, ID, OD), catheter

OLCI and HP OLCI measuring devices in comparison

| OLCI | HP OLCI | |

|---|---|---|

| Measuring method | Low-coherence interferometry | Low-coherence interferometry |

| Measurement wavelength | Glass, plastic, silicon, coatings, paints, films, fluids, air gaps, contact lenses | Glass, plastic, silicon, coatings, paints, films, fluids, air gaps, contact lenses |

| Precision | +/- 1 μm | +/- 10 nm (depending on reference samples) |

| Reproducibility | +/- 0,1 μm | +/- 10 nm |

| Measuring frequency | 10 Hz | 5 Hz (optionally 100 Hz and 200 Hz) |

| Measuring range | 50 μm - 5 mm | 10 μm - 130 mm (opti onally up to 1000 mm) |

| Channels for parallel measurement, by device | 12 | 2 (opti onally up to 6) |

| Dimensions | 19“ 2 U | 19“ 6 U |

| Temperature range | 15 - 30°C | 15 - 30°C |

| Operation at relative humidity | 10-90 % (non-condensing) | 10-90 % (non-condensing) |

| Operating system | Win 7 / 10 | Win 7 / 10 |

| Interfaces | RJ-45 Ethernet | RJ-45 Ethernet |

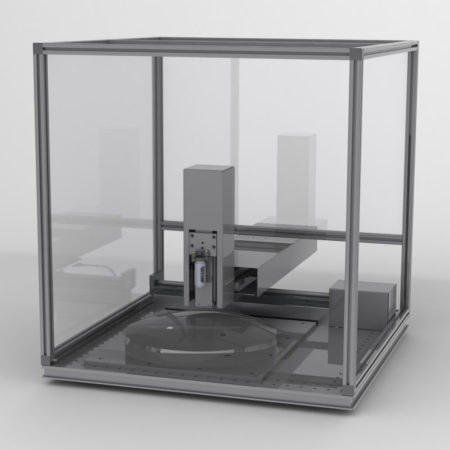

Optional axis system

| Travel (mm) | Precision (μm) | Reproducibility (μm) | |

|---|---|---|---|

| X-axis (scan) | 300 | 20 | 3 |

| Y-axis (scan) | 300 | 20 | 3 |

| Z-axis (focus) | 80 | 20 | 3 |

An axis system makes it possible to create mappings or surface profiles, for example. All axes are driven using stepper motors. Axis systems larger than 300 x 300 mm can also be produced on request.

Axis system dimensions (height x width x depth): 600 mm x 600 mm x 993 mm

Maximum sample size (height x width x depth): 70 mm x 300 mm x 300 mm

Weight: Approx. 55 kg

Download a PDF-factsheet here.